- Tel: 0086-021-37901188

- E-mail: info@triowin.com

- whatsapp: +86 13301885621

- wechat: 13301885621

1.Juice products: Conduct the process test of NFC, concentrated cloudy juice (42Brix), concentrated clear juice(65-70 Brix) and process raw materials such as berries, citrus and tropical fruits as well as small fruit species.

2.Berry products: Conduct the process test of magma and concentrates (28-32 Brix) and process raw materials such as berries, citrus and tropical fruits as well as small fruit species.

3.Fermentation products: Conduct the process test of fruit wine, fruit vinegar, probiotic fermentation, yogurt and other fermented products and process raw materials such as dairy products, pome, nuts, berries, citrus and tropical fruit and small fruit species.

4.Extracted products: Conduct the process test of extracting or concentrating nutrients or active ingredients from all kinds of fruits and vegetables

5.Fruit and vegetable powder products: Conduct the dusting process test of juice or pulp from all kinds of fruits, vegetables.

6.Beverage products: Conduct the process test of color protection, formulation development, sterilization and stability of each fruit and vegetable juice.

7.Pharmaceutical and biological products: Conduct the separation treatment of plasma, animal and vegetable fats, as well as the biological fermentation broth, and set separation factor according to different process requirements.

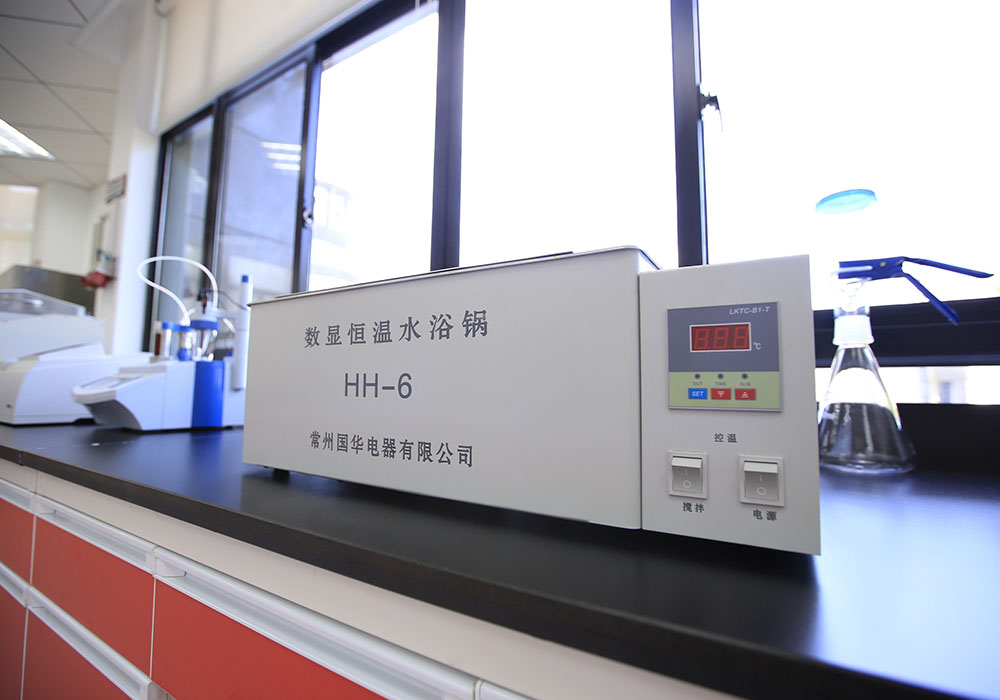

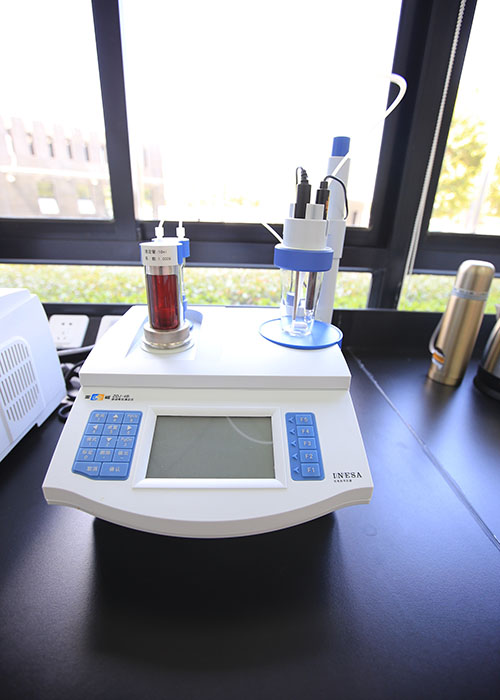

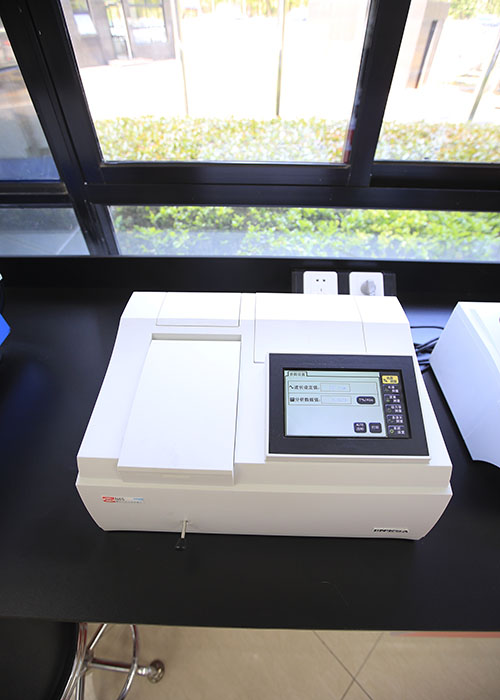

Food Processing Technology R & D Demonstration Engineering Center is a research institution integrating food engineering demonstration, process technology research and food testing. With the science and technology innovation as its core competitiveness, based on independent innovation, it integrates the domestic advanced design concepts and automatic control technology, and holds a team with nearly 70 workers and doctors, masters and senior engineers as the core. It establishes a work flow station for masters, doctor and postgraduate training and post-doctors after actively cooperating with Shanghai Jiaotong University, Tongji University, Shanghai University of Technology, Shanghai Ocean University, University of the South, Central China Agricultural University and many other well-known domestic universities. At present, it covers an area of about 500 square meters, and has more than 90 sets of equipment and instruments. With process rooms, testing rooms, conference rooms, exhibition halls and pilot test workshops, it has a variety of food processing functions.

It provides both domestic and abroad services such as sample manufacture, process technology research, food physical and chemical index test, microbiological indicator test and production pilot test and so on.

Service hotline: 021-37901188 to 8187 Manager Zhang

- Pre-handling Treatment

- Function: Use for cleaning, lifting, breaking, squeezing the process of fruits and vegetables

- Composition: It is composed of air-blowing washing machine, elevator, hammer type crusher, spraying and protecting system, screw press, juice collecting groove, centrifugal pump,screw pump and preheater.

- Principle:Raw fruits and vegetables into the artificial floating washing tank, the air blowing into the water, the formation of full contact surface bubbles and tumbling of raw fruits and vegetables, so as to achieve the purpose of cleaning products. After cleaning by hoist material into the hammer crusher, hammer hammer effect by rotary crusher in 3-5mm, particle size, particle can be different degrees of the material obtained by replacing the screen. The crushing process for inhibiting material enzymatic browning by peristaltic pump adding fixative. The crushed material into the spiral juicer, using spiral cavity gradually reduced, thus forming press to squeeze the juice out of materials. The collected juice collecting groove, the screw pump material into the preheater in the inactivation process.

- Application:For apple, pear, hawthorn, strawberry, raspberry, blueberry, carrots, tomatoes and other pomaceous fruits, berries, fruits or vegetables.

- Pre-cooking, Enzyme Inactiving, Refining System

- Function:Suitable for the pre-cooking, refining and enzyme inactiving of the vegetable & fruit

- Composition:Composed with jacketed pan, refiner, movable screw pump, tubular pre-heater and buffer tank

- Principle:According to the technology requirment, put the material need to be pre-cooked or unfreezed in the jacketed pan, use the steam to heat the water or heat the material directly to the required temperature. After curshing or unfreezing, use the screw pump to convey the material to the pre-heater, heat by the steam until reach the enzyme inactivation temperature, then into the refiner to further refining by hammering of the scraper,the pulp go through the sieve mesh while the pomace separately.

- Application:suitable for all kinds of fruit and tubers vegetable

- Enzymatic hydrolysis separation

- Function:Enzymatic hydrolysis for fruit and vegetable juice, clarification, centrifugation, filtration process

- Composition:By enzymolysis pot, three foot centrifuge, juice collecting groove, centrifugal pump, diatomite filter.

- Principle:Raw fruits and vegetables juice enzyme after passivation into enzymolysis tank by enzymatic clarification, temperature enzymolysis on-line observation control, by double insulation insulation. After the hydrolysis of sustainable materials using three foot centrifuge to insoluble solids separation, the juice collected juice collecting tank, centrifugal pump will be used the material to the diatomite filter filter, fine filter has reached the goal.

- Application:Apply to all fruits and vegetables.

- Blending

- Function:For high-speed dissolved sugar and other additives, grinding, filtering and material allocation process

- Composition:High soluble sugar, double filter, centrifugal pump, grinding and mixing tank

- Principle:Sugar and other additives into water soluble sugar in aqueous solution, driven by rotating the bottom of the high-speed rotation of the impeller, the material is dissolved. The dissolved material can be grinded in a colloid mill according to the technological requirements, make the material more refined. And then into the mixing tank mixing.

- Application:For drinks, jam, wine vinegar, fermented, soluble sugar and mix yogurt fermentation products.

- Deaeration

- Function:Used in the degassing process of fruit and vegetable juice or fruit and vegetable pulp

- Composition:By degassing tank, centrifugal pump, vacuum pump

- Principle:Material through the pump or negative pressure into the degassing tank, under a certain temperature in the vacuum state dispersed into a film or fog point, the oxygen out of the fall of the material using the centrifugal pump or screw pump delivery to the next process

- Application:Applicable to all kinds of fruits, vegetable juice, puree and beverage after application.

- Fermentation

- Function:Used to stir yogurt fermentation, fermented fruits and vegetables, wine vinegar fermentation process

- Composition:From the buffer tank, fermentation tank, storage tank, centrifugal pump, water chiller, heat exchanger.

- Principle:The raw material is adjusted and processed into the fermentation tank, and the fermentation tank is accessed according to the process, the fermentation temperature is adjusted according to different products, and the semi-finished product is fed into the tank after the fermentation.

- Application:Applicable to a variety of dairy products, a variety of fruit, vegetable fermentation.

- in line -homo, Sterilizing&Aseptic Filling Mini-line

- Function:Used for material on line, sterilization, aseptic filling process

- Composition:By UHT 100L/H sterilization machine, homogeneous machine, the composition of the sterile filling room

- Principle:The material into the homogenizer, the liquid will be in extrusion using a reciprocating plunger, strong shock and pressure loss expansion three under the action of the material refinement, so that the material can be mixed uniformly. The homogenized material into the sterilization machine, through the heat exchanger, the material is heated to required temperature and sterilization. For a certain period of time, so as to achieve the purpose of sterilization. After sterilization temperature of filling material through heat exchange to the required. For aseptic filling is required with aseptic filling equipment and filling chamber is to ensure the aseptic state can be.

- Application:Suitable for dairy products, milk products, beverages, fruit juice, concentrated juice, honey and other products.

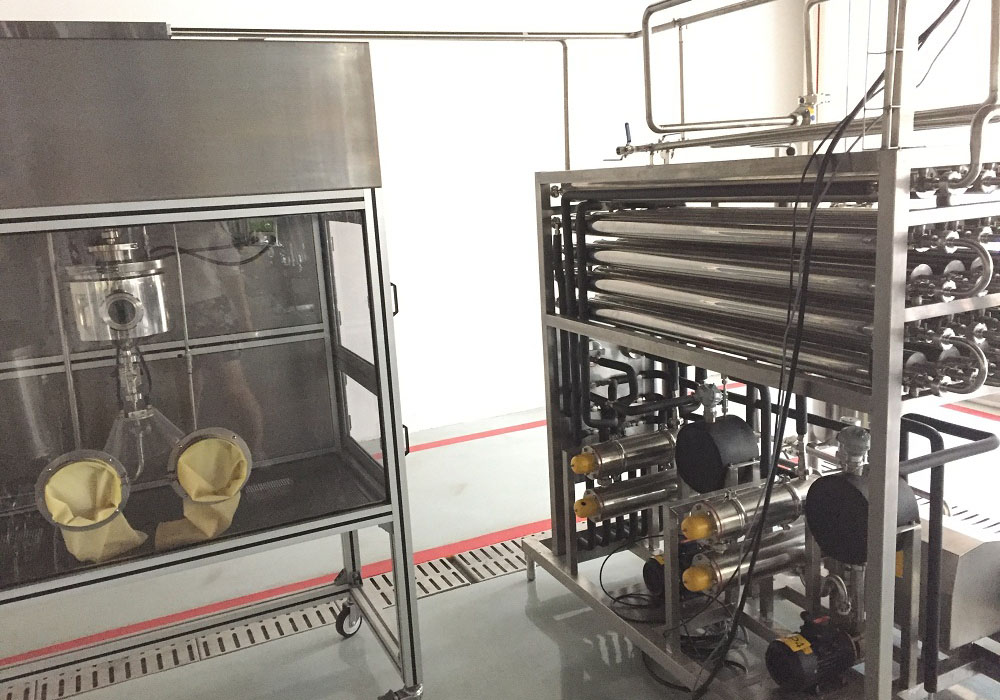

- Disc Separation System

- Function:Separation, clarification ,sterilization and filtration of the liquid.

- Composition:Microfiltration, ultrafiltration, nanofiltration machine, clear juice tank and centrifugal pumps

- Principle:Microfiltration, also known as millipore filtration, is precision filtration, the particles can be trapped between 0.1 to 1 micron, macromolecular organic matter and inorganic salt will be allowed to pass through the microfiltration membrane, but it can stop the suspended solids, bacteria, viruses, and part of the large-scale colloids; Ultrafiltration use the pressure difference of the membrane on both sides as driving force, with ultrafiltration membrane as the filter medium , at a certain pressure, when the liquid flows through the membrane surface, with many tiny pores allow only water and small molecule material pass through and become permeate liquid, while larger than the volume of liquid in the micro-pore size of the membrane surface material were trapped in the feed side of the membrane, to become concentrated liquid, thereby achieving the purification of the liquid, the separation and enrichment purposes. Nanofiltration membrane, refers to a "nano-scale" membrane, it is between ultrafiltration and reverse osmosis, and for the inorganic salt has certain intercept rate and the membrane with molecular weight cut off from 200 ~ 1000 Dalton optional.

- Application:Apply to Fruit juice beverage industry, bio-fermentation, bio-medicine, chemical industry, water treatment industry, environmental protection industry and other fields.

- Double-effect Falling Film Concentration Unit

- Function:be used to concentrate process for fruits juice, dairy and other liquid.

- Composition:Heaters, separators, condensers, centrifugal pumps, screw pumps, vacuum pumps, Steam valve group, material tanksc

- Principle:After the material enter into the material tank by a centrifugal pump to feed liquid from the header of the heating chamber, by means of liquid distribution and film device, evenly distributed into the respective heat transfer tubes, along the inner wall of the tubes flow down. In this process, evaporated by heat of the heating medium, the generated liquid and the vapor enter into the common separation chamber of the evaporator, vapor-liquid separate sufficiently, the steam entering the condenser and then cooling into the next effect evaporator as the heating medium, in order to achieve more efficient operation, the liquid is discharged by the separation chamber. Evaporation of water 35L / H, single-effect evaporation temperature 75 ℃, the second effect evaporation temperature 48 ℃, cooling water consumption 1T / H, steam consumption 18Kg / H

- Application:Apply to milk, juice, glucose, starch, xylose, pharmaceutical, chemical, biological engineering, environmental engineering, waste recycling.

- Disc Separation System

- Function:Used for turbid liquid separation of turbid liquid or emulsion , or liquid-liquid separation process

- Composition:SE03V Experimental centrifuge, Collection juice tank,centrifuge pump

- Principle:Disc centrifuge using an intralipid( or emulsion) different densities of the components in the centrifugal field of rapid sedimentation stratification principle to achieve liquid-solid (liquid-liquid) separation. It is a kind of separation equipment, which is using high-speed rotating drum drive the material produce centrifugal force to strengthen the separation process . Along the drum center (axial feed) feeding material, thin layer between the disc inflow along the radial direction, under the influence of centrifugal force flows down the outside, and finally be left to the drum wall. Low density flow to the center, with overflow out. Since the disc separating chamber into several layers, reducing the settling distance of the particle, thereby shortening the settling time, accelerates the process of centrifugal separation.

- Application:Apply to food engineering, bio-pharmaceutical, oil and chemical industry energy industry.

- Pneumatic Vaccum Press System

- Function:Be used to extraction process of the berries fruits

- Composition:SIPREM Experimental Vacuum press

- Principle:After the raw juice is poured into the press, close the door, turn on the pump, make the compressed air continuously go into the gasbag, with the pressure increasing, balloon increasing pitch airbags and increasingly juicing chamber the smaller, the material in the gap by increasing pressure balloon, sap flow, when the balloon pressure reaches a certain pressure, juice complete the process to achieve the slag material, juice separation. Juicing process can be set and re-press to improve the effect of juice to improve juice yield, according to the set procedures.

- Application:Apply to grape, strawberry, mulberry, raspberry, blueberry and other berry fruits.

- CIP System

- Function:Be used to on-line cleaning process of the processingl line

- Composition:Water tank, alkali tank, acid tank, centrifugel pump, plate heat exchanger

- Principle:Centrifugal pump make the raw water through into the reverse osmosis units, reverse osmosis, also known as reverse osmosis, use the pressure difference as the driving force, membrane of the separation solvent is separated from the solution. Using the of a booster pump to exert pressure on the solution side of the membrane, when the pressure exceeds its osmotic pressure, the water will penetrate against natural direction for reverse osmosis. Whereby the low pressure side of the membrane get the solvent, that is pure water, it will go into pure water tank; obtain a concentrated solution on the side of high-pressure, that is concentration water, it can be reused or discharged into the sewer.

- Application:Apply to beverage, dairy, juice, puree, jam, wine and other high degree of mechanization in the food and beverage manufacturers.

- Pure Water Manufacturing System

- Function:Be used in pure water manufacturing process

- Composition:Raw water tank, water storage tanks, reverse osmosis unit composition

- Principle:Centrifugal pump make the raw water through into the reverse osmosis units, reverse osmosis, also known as reverse osmosis, use the pressure difference as the driving force, membrane of the separation solvent is separated from the solution. Using the of a booster pump to exert pressure on the solution side of the membrane, when the pressure exceeds its osmotic pressure, the water will penetrate against natural direction for reverse osmosis. Whereby the low pressure side of the membrane get the solvent, that is pure water, it will go into pure water tank; obtain a concentrated solution on the side of high-pressure, that is concentration water, it can be reused or discharged into the sewer.

- Application:Apply to beverage, dairy, juice, fruit purees, jam , wine, etc

- PET Bottling Packaging System

- Function:Suitable for rinsing, filling and capping

- Composition:composed by conveyer system and Monobloc rinsing-filling-capping

- Principle:After sterilizing, the product enter into the filling machine to be filled, while conveyor system conveys the PET bottles to the rinser for washing before filling, after filling, the PET bottles enter the capping system for sealing.

- Application:Suitable for fruit juice beverage

- Single-effect rising film evaporating system

- Function:Suitable for the concentration of juice, pulp and viscosity material

- Composition:Composed with 10L rising film evaporator and steam generator

- Principle:Add the material into the material tank, feed the material by the centrifugal pump through the bottom of the pre-heater. Inject steam to heat the material, after substantial evaporation of vapor phase, the material is rising as the film along the wall by high speed under the function of vacumm. The material and the vapour phase separate in the separation chamber, the vapour is condensed into water in the condenser while the material back to the material tank, repeat the evaporating until reach the desired concentration.

- Application:Suitable for fruit&vegetable juice, herbal medicine,pharmacy, glucose, animal&plant protein, wine, starch, oral liguid, chemicals, health food, pigments, additives, MSG and etc.

- Mini-processing Plant

- Function:Suitable for the homogenizer on-line, sterilizer and aseptic filing of the material

- Composition:Composed with PT-20T tubular sterilizer, homogenizer and aseptic filling cabinet

- Principle:Simulate the industrialized production situation completely, set the sterilizing temperature and holding time according the technology. After preliminary heating, the material go into the homogenizer for homogenizing, emulsifying, then cooling to the filling temperature by heat exchanger, hotting filling or normal filling available. This can be scaled directly into the industrial production after the experimental date and conclusions are correct.

- Application:Suitable for dairy product,soy products, beverage, juice, concentrated juice, honey and etc.

- Multi-function Extraction and Concentration System

- Function:Suitable for grinder, extraction and concentration

- Composition:Composed with grinder, ultrasonic extraction tank, multi-function concentration

- Principle:After grinder, the materila will be added into the ultrasonic extraction tank, use the mechanical effect, cavitation effect and thermal effect of the ultrasound,by increase the medium molecular's velocity of movement and penetration power to extract the effective composition. The extraction solution enter into the multi-functoin concentration material tanks, with the centrifugal pump conveys to the heater and separater to finish the heating, steam-water separation,organic solvent recovery, aroma recovery and concentration process.

- Application:Suitable for chinese herbal& natural product's extraction and concentration (water and organic solvents) and recyclic of volatile aromatic oils