- Tel: 0086-21-37901188

- E-mail: info@triowin.com

- whatsapp: +8613301885621

- wechat: 13301885621

Youtube video link:https://youtu.be/EVWEkOyK2Qc

Shanghai Triowin Intelligent Machinery Co., Ltd import the most advanced technology from Italy, Europe and America, combine with the investment characteristics of Chinese mainland, and form brilliant technical program for citrus processing line. Customized design is available based on the investment and actual production situations of enterprises, realize real turn-key project for customer. We are committed to developing innovative equipment to improve the entire operating efficiency, decrease downtime period due to maintenance and reduce capital investment greatly.

1.Introduction of Citrus Processing Line

Triowin produces orange extractor and citrus processing equipment for the global market. Our Citrus Extractor is the heart of citrus processing system and we are the industry leader in citrus extraction technology in China.

2.Features of Citrus Processing Line

- * The entire production line can also deal with the same characteristics of the fruit, such as orange, lemon, etc..

- * 3 models of the juice extractor can be choosed.

- * According to the needs of customers can determine whether the need to separate the essential oil system.

- * The final product can ensure the original nutrition and flavor.

- * The advanced enzymatic hydrolysis separation system ensures the product quality and yield.

- * According to the requirements of customers can choose to focus on the import and domestic.

- * Full use of man-machine interface control, the production process is intuitive and easy control and operation, high automation, reduce labor costs.

- * The whole production line includes automatic cleaning system.

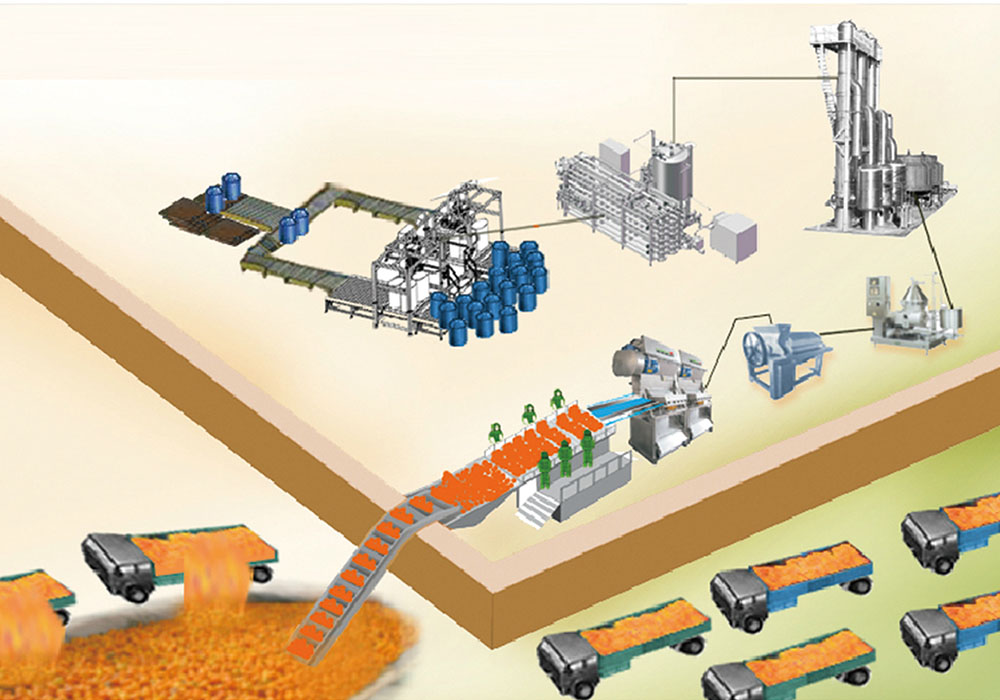

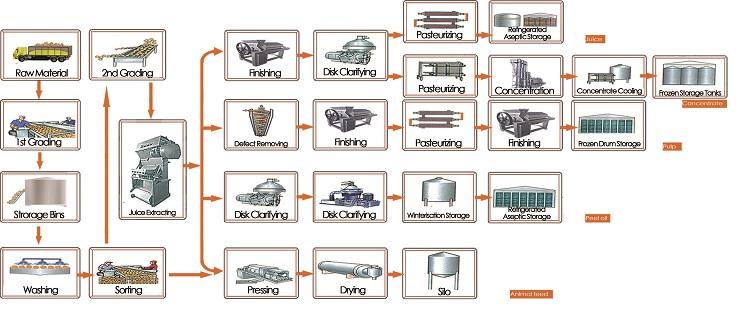

3.Processing of Citrus Processing Line

- Fruit receive and first step cleaning;

- Fruit storage system with elevator and storage bin;

- Fruit cleaning and sorting;

- Fruit grading to different sizes group;

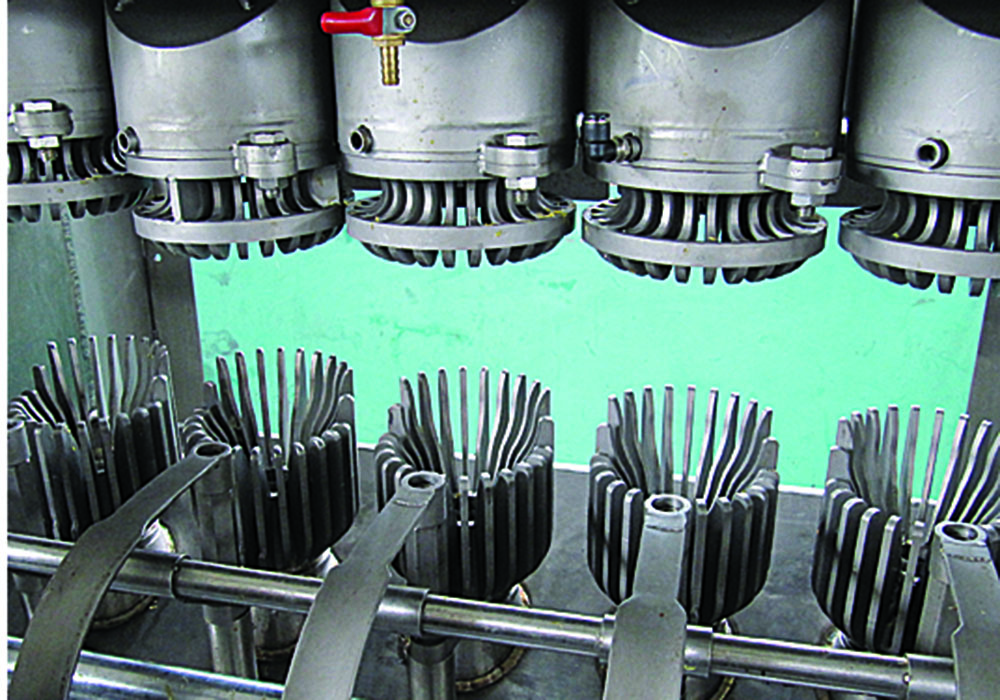

- Cup-type squeeze extractor;

- Juice refiner and separator;

- Concentrating by evaporator;

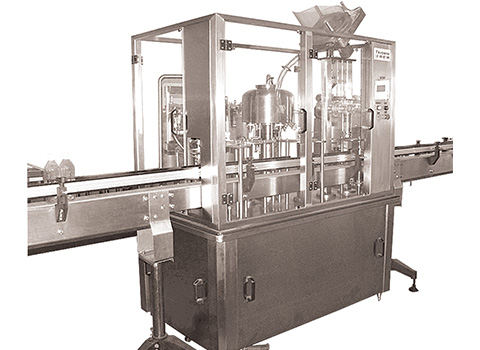

- Pasteurizer and aseptic drum filler;

- Fruit pulp refiner and sterilizer;

- Fruit oil collection and separator;

- Fruit peels drying system to make animal feed;

- CIP cleaning system;

- Installation and commissioning, training.

4.Turnkey Project Flow Diagram

|

Raw material |

Citrus, Fresh orange, lemon, etc. |

|

Finished product |

Concentrated Juice, NFC Fresh Nature Juice,Oil,Orange pulp |

|

Processing capacity |

From 20tons/day to 2000 tons/day |

|

Efficient input |

45% raw fruit (55% as waste, peels and seeds) |

|

Fruit consistence |

7~12Brix |

|

End package |

Aseptic bag/tin can/glass bottle/PET bottle |

|

Output |

Can be calculated |

6.End Product

7.Related Machine