- Tel: 0086-21-37901188

- E-mail: info@triowin.com

- whatsapp: +8613301885621

- wechat: 13301885621

1.Description

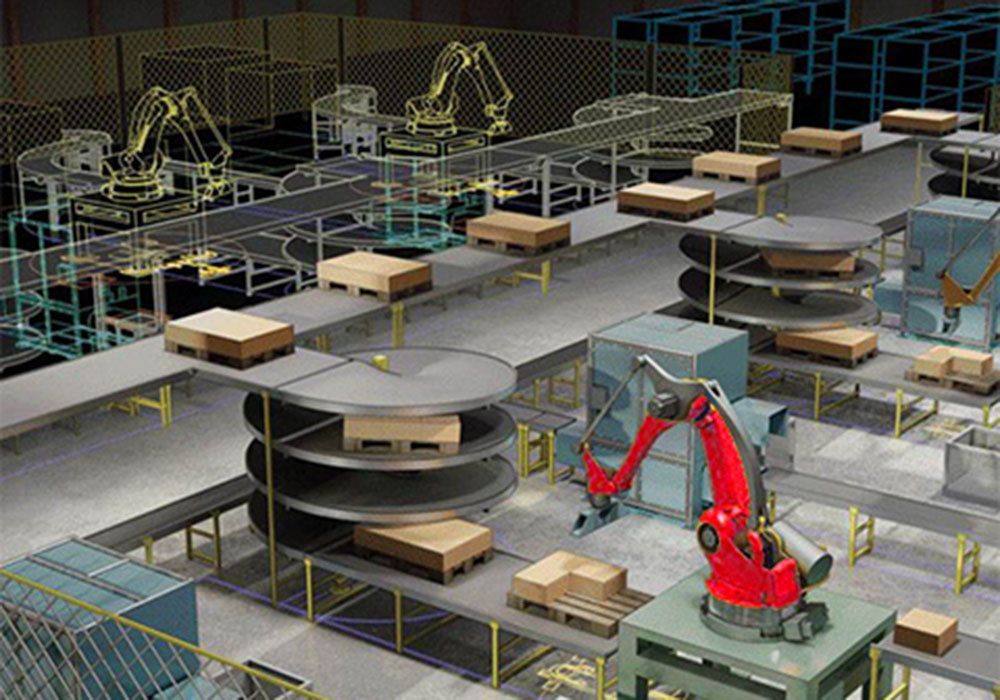

The full life cycle solution of the Triowin intelligent digital factory covers two major stages: the planning construction period and the commissioning operation period. In the planning phase, the future operation mode and manufacturing mode are deduced to realize data-based decision-making and future-oriented planning. In the operation phase, equipment state acquisition and intelligent analysis technology are taken as the core to create a more transparent manufacturing execution process and smarter production management decisions, thus building a "virtual and virtual integration(virtual- real fusion)" intelligent manufacturing system.

1. Top-level planning, intelligent manufacturing planning for Industry 4.0

The benchmark "Industry 4.0" meets the new factory construction goals of "interconnect, lean, intelligent" etc, supporting advanced manufacturing modes such as "mass customization", adopting 3D visualization, factory simulation and virtual-reality technology, and integrating management philosophy with lean production, personalized customization, etc. Using industry-leading planning methods, to provide enterprises with intelligent manufacturing maturity evaluation and path planning for intelligent manufacturing.

2. Implementation plan

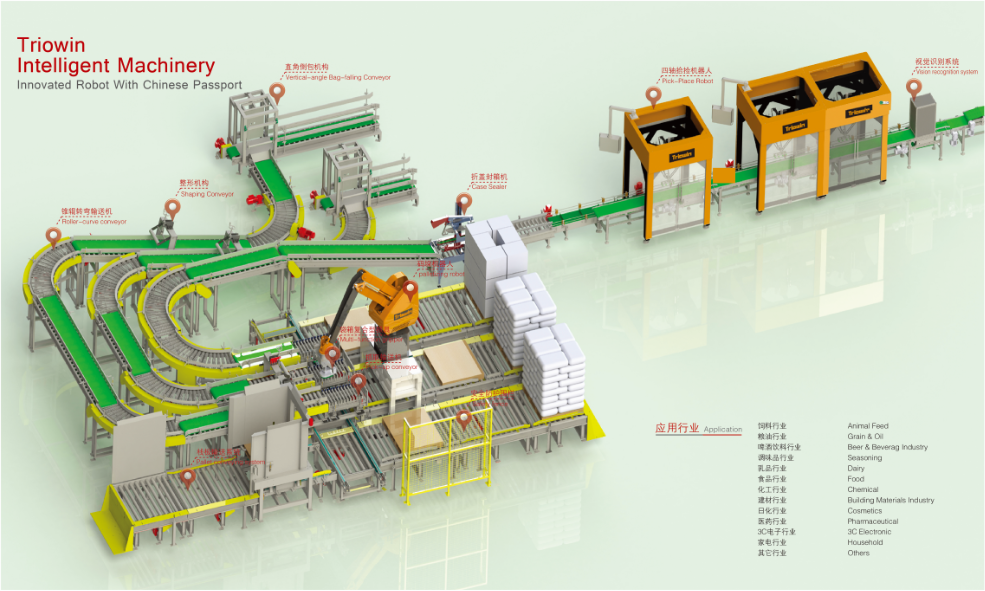

1) layout planning and simulation optimization

2) Warehousing planning and simulation optimization

3) Logistics planning and simulation optimization

4) Logistics planning and simulation optimization

Facing the vision of “Made in China 2025” and “Industry 4.0”, combined with the strategic goals of the company, we plan to support the vertical integration and horizontal coordination of the plant layer information system.

3. Put into operation

1) Data acquisition system

Help enterprises to realize the whole equipment networking covering production equipment, testing equipment and other auxiliary equipment, and real-time collection and analysis for equipment status and production operation status data.

Ø Device interface selection and networking services

Ø Equipment status parameter collection service

Ø Enterprise centralized control management service

2) Intelligent production management system

The intelligent production management system serving as the link between the upper-level planning management system of the manufacturing enterprise and the underlying industrial control, focuses on solving the effective implementation of the workshop operation plan, improving the transparency of process, increasing the efficiency of execution and improving the quality of product as a whole. By obtaining real-time data of the manufacturing process, such as current order status, production capacity, production cost, product quality, manufacturing cycle and estimated output time,etc., it provides optimization basis and decision-making basis for the upper management system; helping the company realize the whole process of production, people, machines and materials , law, environmental science management and full traceability to achieve transparent production.

3) Three-dimensional mapping system for production state

4) The management system of equipment maintenance and repair

4. Continuous improvement

1) Simulation-based lean improvement

Based on the simulation model of virtual factory, the existing production system is evaluated and predicted, including verifying the rationality of the shop layout, verifying the rationality of the shop logistics, etc., dynamically adjusting the plant's overall planning and continuous simulation analysis and evaluation, and proposing plans for optimization and improvement.

2) Industrial data analysis

Based on big data analysis to improve the ability of enterprises to sort out the vast amount of information collected by different devices, it improves the computing power and data digestion ability of enterprise information systems, enabling enterprises to realize on-demand production effectively and Improving the operating efficiency of the enterprise. Based on big data analysis for detailed evaluation and prediction of production operation status to propose optimization and improvement programs.