- Tel: 0086-21-37901188

- E-mail: info@triowin.com

- whatsapp: +8613301885621

- wechat: 13301885621

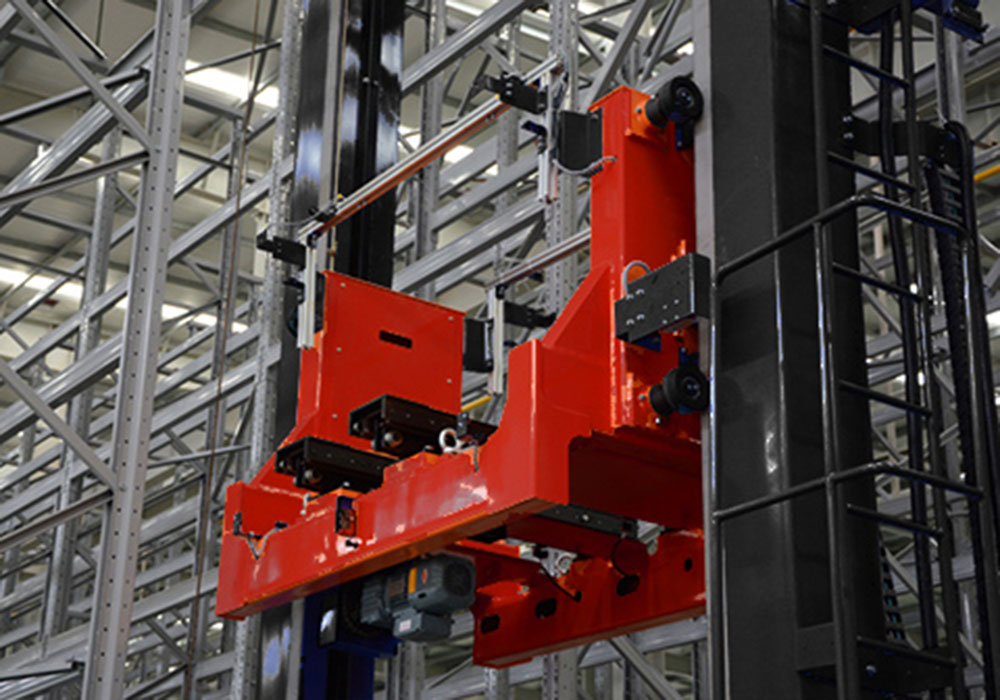

Palletizing is the main automated warehouse handling equipment that runs in high shelf.The performance of stacker directly affects the operating efficiency and cargo damage rate. It is important to improve the running speed and running smoothness.

Rail stacker is a main device among the shelves equipment. It can Reciprocatingmove in three dimensional space as orders to complete the operation of out and in the library. It consists of upper beams, lower beams, columns, horizontal running mechanism, lifting mechanism, cargo units, forks and electrical control system.

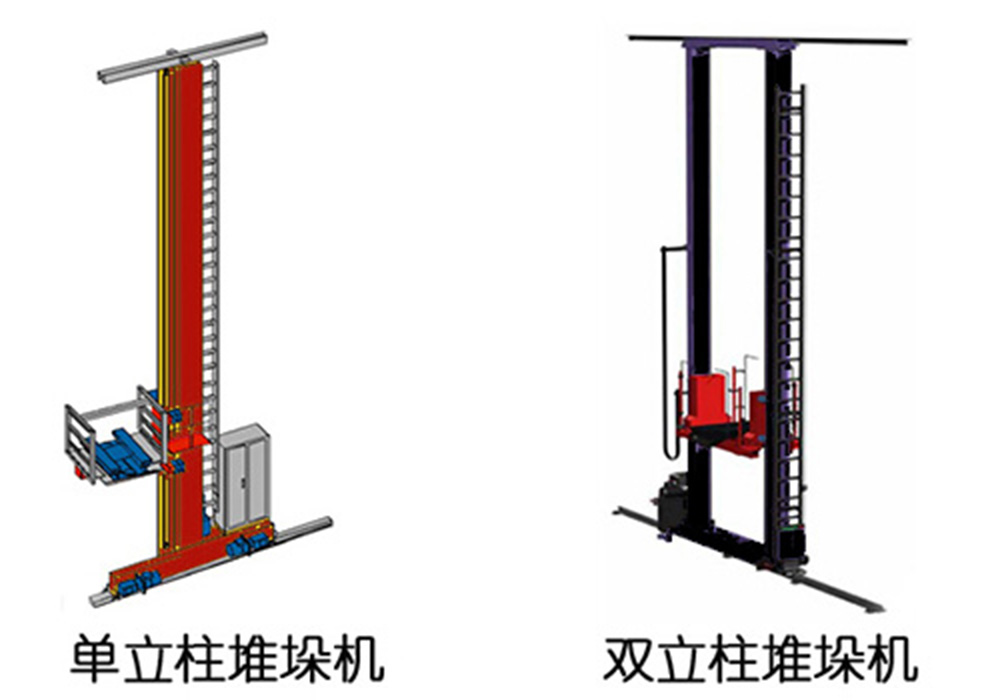

There are kinds of stackers such as single rail stacker, two rails stacker, single column stacker and two column stacker.

There are three running modes include manual operation, semi- automation and full automation. During fully automatic control, monitor computer sends the operation order and bit to stacker, and stacker executes the order. During manual operation and semi-automation, operator imports operation by stacker HMI.

Parameters

|

Load |

50kg-3000kg |

|

Walking speed |

60m/min—200m/min |

|

Lifting height |

25m/min—80m/min |

|

Fork expansion speed |

10m/min--)60m/min |

Configuration

*Three driving motors make stacker move in horizontal, vertical and Forward and backward directions.

*2 laser rangefinders are used to reader the position of stacker in horizontal and vertical direction.

*The stacker control unit communicates with the central control system via laser communication.

* The horizontal moving driving motor and fork moving driving motor use the same inverter.

* The power supply is by sliding contact line.