- Tel: 0086-21-37901188

- E-mail: info@triowin.com

- whatsapp: +8613301885621

- wechat: 13301885621

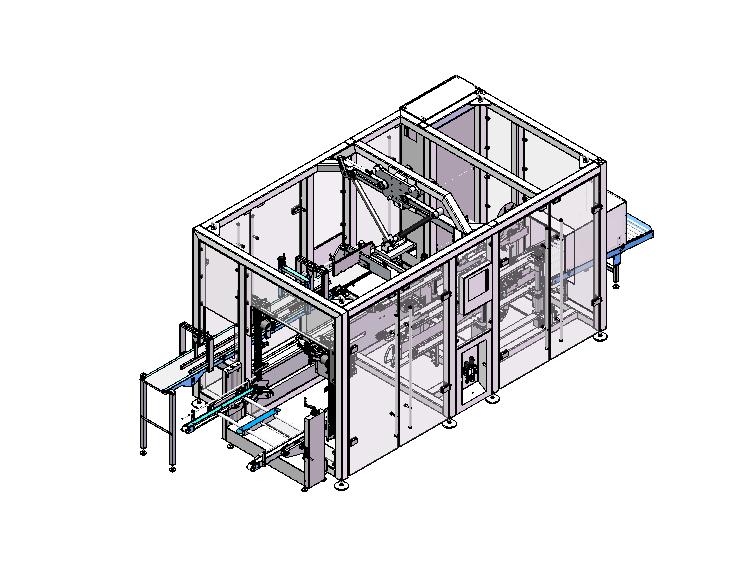

Triowin company's (top-in boxing integrated machine) mainly consists of the following parts:

Device parameters

1. Feed conveyor system

2. Permutation stack system

3. Packing robot unit

4. Tape sealing unit

5. conveyer belt

Working principle

Small boxes, medium bags or bottle products enter the feeding system, and the packing machine shall arrange the small boxes, medium bags or bottle products in the arrangement system according to the user's specifications (how to arrange the boxes, medium bags or bottle products, and the layer * column);

After the arrangement and finishing, the product group is stably sent to the carton by the packing robot. The products in the carton are tested to meet the user's specifications, and the carton is sent to the sealing unit, sealed with adhesive tape, and then discharged to form a stable carton packaging.

Main function

It is suitable for packing small boxes, middle bags or bottles and other products, which can protect products (moisture-proof, dust-proof and outer surface) and logistics transportation. It is mainly suitable for pharmaceutical, daily chemical, food and beverage industries.

Equipment pictures

Features

1. Balcony design, in line with GMP standard

2. The stepped design of the material conveying unit in carton ensures the same absorbing condition every time

3. Carton conveyor belt four vertical box fingers, to ensure the appearance of the sealing neat

4. Mechanical and moving parts isolation, high safety standards, easy to clean

5. Easy operation

6. The last batch of products will not be left behind when the specification is converted

7. Easy specification conversion

Device parameters

Equipment size

6200 x 2200 x 2680 mm [Length x Width x Height]

weight

2600KG

carton size

corrugated case

Sealing way

tape

Minimum specification range

Packing products 30 x70 x 15 mm [Length x Width x

Height]

Maximum specification range

Packing products 580 x 250 x 250 mm [Length x Width x

Height]

Speed

maximum 12 cases/min

Voltage/power

380V/10KW

low-voltage

6-8 Bar

Carton 200 x 150 x 150 mm [Length x Width x Height]

Carton 600 x 400 x 400 mm [Length x Width x Height]

List of components

Controller Embedded PLC

BECKHOFF OR The same brand

servosystem

BECKHOFF OR The same brand

reduction gears

Alpha precision reducer

low-voltage

Schneider