- Tel: 0086-21-37901188

- E-mail: info@triowin.com

- whatsapp: +8613301885621

- wechat: 13301885621

Overview:

This equipment is designed and manufactured by our company integrated with advanced technology at home and abroad. It is specially used for sterilization of different viscosity materials such as medicine, food, biochemical, plant extracts, etc. It adopts special multi-group tube casing structure. The material can be sterilized at high temperature for rapid sterilization in a very short period of time to ensure that the active ingredients of the material are not damaged and loss ,and the color of the product does not change.

Parameter

|

Parameter |

UHT-0.5 |

UHT-1.0 |

UHT-3.0 |

UHT-5.0 |

UHT-10.0 |

|

Capacity (t/h) |

0.5 |

1 |

3 |

5 |

10 |

|

Steam pressure (MPa) |

0.6 |

||||

|

Sterilize temperature (℃) |

95--138 |

||||

|

Sterilize time (s) |

3--45 (adjustable) |

||||

|

Material inlet temperature (℃) |

25--50(adjustable) |

||||

|

Material outlet temperature (℃) |

25--50(adjustable) |

||||

|

Steam consumption (kg/h) |

55 |

100 |

280 |

450 |

870 |

|

Power (kw) |

2.75 |

3.5 |

6.5 |

8 |

11 |

|

Size (m) |

3x1.5x1.6 |

3.3x1.6x1.8 |

4.5x1.8x2.0 |

4.5x2.0x2.0 |

4.5x2.0x2.0 |

|

Weight (kg) |

1760 |

2000 |

2650 |

3080 |

5300 |

Performance characteristics:

a. The temperature difference between the heating medium and the material is small, and mild heating can be realized. The heat exchange tube adopts a sleeve type, double mirror polishing, less fouling, which increases the working time of the sterilization machine and is not easy to coke.

b. The inner and outer walls of the material tube are polished by advanced technology, the pipe welding is automatically welded, the pipe is designed for completely automatic cleaning, and the whole process is automatically sterilized to ensure the sterility of the system.

c. Sterilization temperature control is accurate and reliable: systems affecting sterilization temperature such as steam pressure, flow rate, material flow rate, etc. are strictly controlled automatically.

d. High degree of automation, automatic control and recording can be realized from CIP cleaning of equipment, self-sterilization of equipment to sterilization of materials.

e. The system is highly secure, and the system components are all selected with high performance and high reliability. The system structure is reasonable in design, compact in structure, easy to operate. Steam, hot water and materials all have pressure protection measures and alarm system.

f. The system has high reliability. The main components such as material pump, hot water pump, various valves, electrical components and actuators of the control system can are world famous brands, and the quality is safe and reliable.

g. Equipped with CIP cleaning system and SIP system.

Structural characteristics:

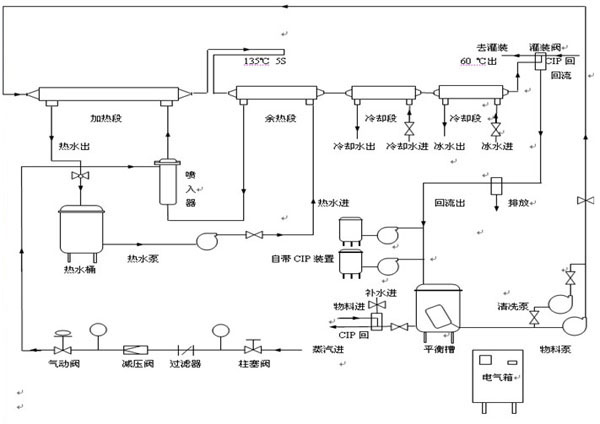

The tube in tube sterilization system consists of material storage tank, superheated water tank, transfer pump, tubular heat exchanger, steam inlet system, valve and pipes, sensor, induction switch, PLC automatic control system and control cabinet. The main body is divided into hot and heat material heat recovery section, preheating section, sterilization temperature holding section and cooling section. The whole sterilization process is fully automatic, and the human-machine interface can flexibly set the sterilization temperature. During the production process, the temperature difference between the upper and lower sterilization temperatures does not exceed 0.5 °C. It is equipped with a pressure multi-functional tank. It is used to buffer the backflow of materials and materials during production. It can be used as CIP cleaning tank after production. The device adopts high-end configuration, the operation is simple and convenient, the sterilization parameters required are set, and the sterilization process can be completed automatically by one-button operation without human intervention. The sterilizer adopts direct heat exchange of hot and cold materials to achieve temperature rise and temperature drop, which is about 30% energy saving than the same sterilizer in the industry.

Relevant equipment:

工艺流程: