- Tel: 0086-21-37901188

- E-mail: info@triowin.com

- whatsapp: +8613301885621

- wechat: 13301885621

Youtube video link:https://youtu.be/X-bWYAGmvl4

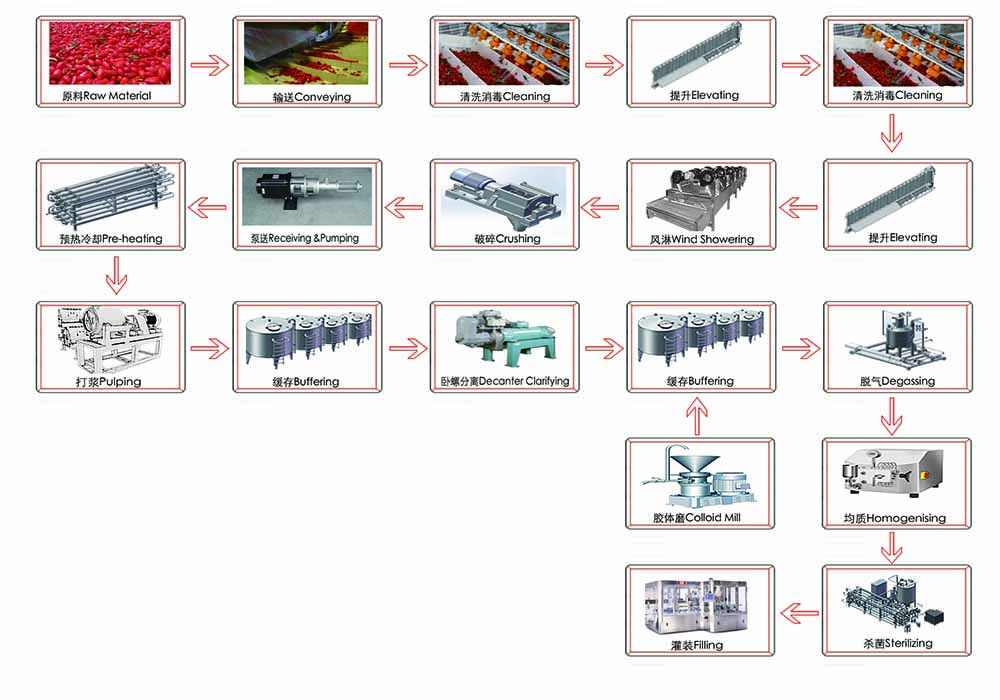

Suitable for processing of wolfberry, to produce clear juice, turbid juice, juice concentrate, wolfberry powder, medlar wine products, etc. This production line is mainly composed of cleaning machine, elevator, air shower, pre-heater, pulper, horizontal spiral separator, degasser, homogenizer, sterilization machine, filling machine equipment, etc. This production line design features advanced design idea, high degree of automation; Main equipments are all made of high quality food grade stainless steel, accords with the hygienic requirements of food processing.

Features

*Capacity varies from 2tons/day to 200tons/day.

*Able to handle wolfberry process

*Can produce clear juice, turbid juice, juice concentrate, wolfberry powder, medlar wine products

*Through pre-heating treatment to increase the rate of juice

*Through degasser to exhaust oxygen to provent from browning

*Through two-stage homogenizer to prevent material from layering.

*The whole line features high automatic degree, saves labor power remarkdly.

*Build-in CIP system to make clean easy

*Material contact part of the whole system is 304 stainless steel material, fully meets the food hygiene safety requirements.

Parameters

|

Raw material |

Wolfberry |

|

Finished product |

Clear juice, turbid juice, juice concentrate, wolfberry powder, medlar wine products |

|

Capacity range |

2tons/day to 200tons/day |

|

Fruit wine |

fermented drinks, distillation wine, sparkling wine |

|

Brix of juice |

15~20Brix |

|

Brix of concentrate |

36~65Brix |

|

Package options |

Pull-ring can/tetra pak/ glass bottle/PET |

|

Design capacity |

According to clients’ requirements |

Flow Chat