- Tel: 0086-21-37901188

- E-mail: info@triowin.com

- whatsapp: +8613301885621

- wechat: 13301885621

-

1.Description

Triowin Aseptic Filling Systems offer a highly effective and reliable aseptic method of bulk packaging for high and low-acid food products, including tomato paste, vegetables and fruit juices, purees, particulates, concentrates, sauces, soups and dairy products.

-

-

2.Paste Aseptic Filler

The Aseptic Filler receives drums or bins through roller conveyors. The containers can be drums in a single line, drums on a pallet (4 drums) and bins. The operator places the presterilized bag in the container then they are automatically transported under the filling station. The presterilized bag is manually placed under the aseptic chamber in a sterile environment saturated by overpressure steam. The operator pushes the start cycle and automatically the cap is removed, the bag filled with sterilized product and then recapped. The standard measure system is with load cells but also the volume system is available. At the end of the filling cycle, the roller conveyor transports the containers to the exit.

Model

TW8E3000S(Single head)

TW8E8000D(Double)

capacity(L/H)

1000-3000

4000-8000

power(kw)

1

1

Steam consumption(0.1mpa)(kg/h)

20

40

Compressed air consumption(8kg/cm2)

20

40

Maximum weighing range(kg)

2000

2000

Weighing error

±1%

±1%

Dimension(mm)

2500*2000*2500

3700*2000*2500

-

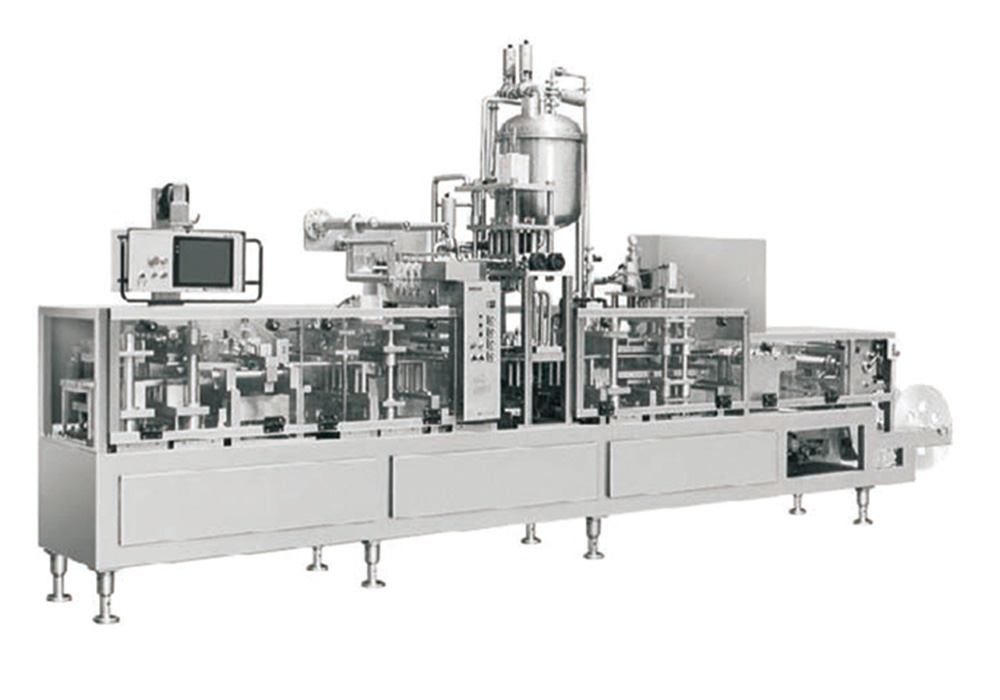

3.Aseptic Liquid Filling Machine

This machine is mainly used to rinse the empty bottles, fill the prepared product in and then cap the PET bottles. It is mainly composed of bottle in feeding unit, rinser, transition thumb wheel, filler, Capper, Bottle outlet stat wheel. Adopt particular design to suspend bottleneck, which can effectively resolve the trouble such as the operation is failed because the bottle is too thin or the high temperature of hot-filling which make the bottle deformed. Provided with CIP washing function which can effectively wash filing barrel and all sanitary pipes before and after the operation.

Type

TWRFC20-20-10

Processing capacity

10000BPH

Compressed air

0.7Mpa, 1m3/min.

Water consumption

3 tons per hour

Total power

10KW

Dimension

4360x3300x2600mm (L×W×H)

Gross weight

9000kg

Applicable bottle diameter

50-90mm

Applicable bottle height

165-290mm

4.Can Drink Filling Machine

This filling & seaming monoblock is suitable for canned viscous fluid such as paste, sauce, jam, milk, honey, grease and product with short fiber or particles in cylindrical containers-aluminum or metal tins/cans. It consists of filling machine, tin seamer, synchronous conveying and PLC control system.

1. Piston volumetric and rotary filling style with 12 filling heads.

2. Automatic product pumping controller.

3. If applies for filling kinds of paste, high viscous materials and concentrated juice etc.

4. High running stability and precise filling station

5. Equipped with material mixing system, it is three points liquid level controlling.

6. Automatic speed adjustment and made from high quality stainless steel, it has beautiful surface and confirms with foodstuff sanitation requirements.