- Tel: 0086-21-37901188

- E-mail: info@triowin.com

- whatsapp: +8613301885621

- wechat: 13301885621

Overview:

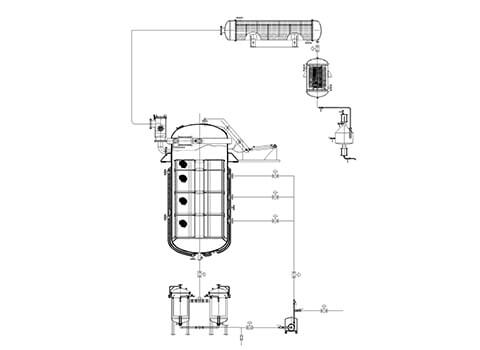

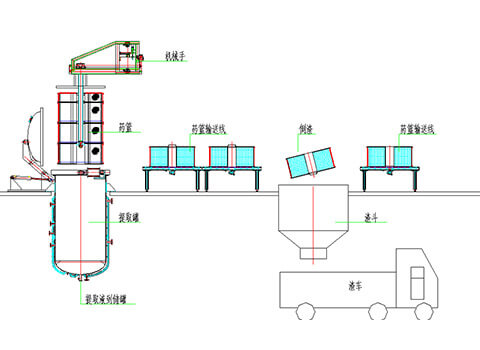

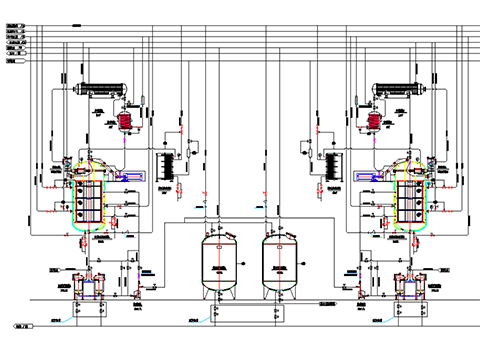

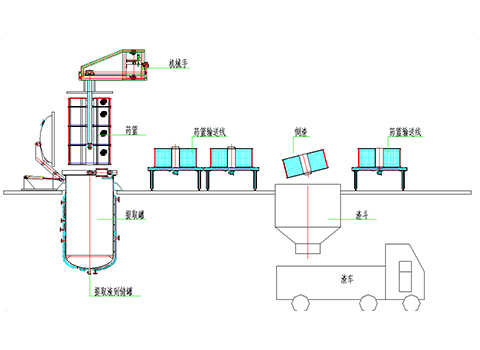

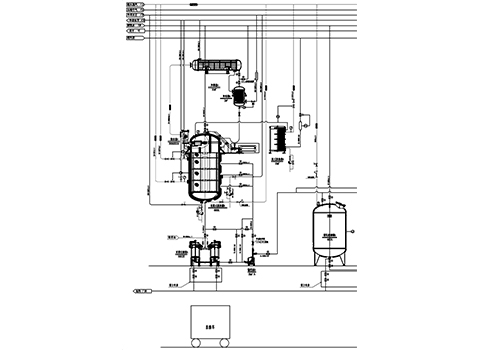

The equipment consists of an extraction tank body, a demister, a condenser, a cooler, a water separator, a filter, a transfer pump, a medicine basket, a robot, a basket device, a demolition device, a medicine basket medicine flow line, and a medicine basket. It consists of cleaning equipment, drying equipment, and automatic control system. It is suitable for medicinal materials that are easy to float and roots and leaves. Its extraction rate is much larger than that of conventional extraction tanks.

Control options:

1. Automatic feeding control

2. Solvent flow control

3. Liquid level automatic control

4. Extraction immersion / insulation / temperature rise, boiling temperature and time automatic control

5. Forced recirculation loop logic control

6. The micro-boiling automatic control

7. Feeding quantity measurement control

8.CIP automatic cleaning

9. Bottom recoil control

10. Interlocking and protection of the upper cover door opening and closing device

11. Cooling circulating water automatic control

12. Production safety control

13. Control mode (PLC/DCS system)

Advantages:

a. The medicine adopts the automatic feeding and discharging mode of the upper and the upper, which reduces the labor intensity and greatly improves the safety of the workshop production.

b. The medicine is collected in the medicine basket so that it is fully in contact with the solvent. And the distribution is relatively uniform. The accumulation degree is low.

c. The medicinal material is in a suspended state, and does not have a liquid surface, which greatly enhances the efficiency of the precipitation of effective substances and shortens the extraction time;

d. It can realize online automatic control and reduce the extraction production time from the feeding to the final discharge slag, cleaning and other processes.

e. It is also possible to perform internal and external circulation for boiling

f. Short slag discharge time and high efficiency;

g. The whole process of the system is highly automated by lifting the medicine basket and the dregs from the tank by robot or driving after the discharge is completed and carrying out the subsequent slag, cleaning, and drying of the basket.

Process flow: