- Tel: 0086-21-37901188

- E-mail: info@triowin.com

- whatsapp: +8613301885621

- wechat: 13301885621

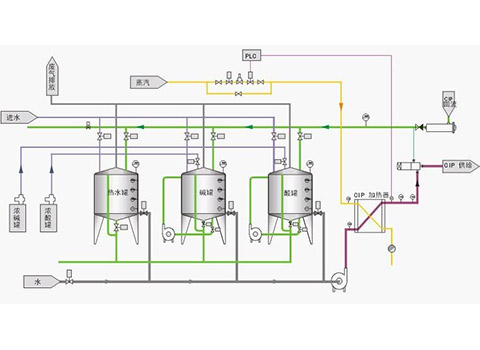

CIP cleaning system, commonly known as in-situ cleaning system, is widely used in fermentation engineering, food and beverage, dairy, jam, alcohol and other highly mechanized production enterprises. In-place cleaning is referred to as CIP, also known as cleaning positioning or cleaning in place. In-situ cleaning means that the device is not used to disassemble or move the device, that is, the high-temperature, high-concentration cleaning solution is used to strongly filter the contact surface with the food for the production equipment, it used for the cleaning and purification of strict hygiene requirements.

|

Specifications |

CIP-0.5 |

CIP-1.0 |

CIP-2.0 |

CIP-3.0 |

CIP-5.0 |

CIP-10.0 |

|

Pickling tank |

500L |

1000L |

2000L |

3000L |

5000L |

10000L |

|

Alkaline washing tank |

500L |

1000L |

2000L |

3000L |

5000L |

10000L |

|

Hot water tank |

500L |

1000L |

2000L |

3000L |

5000L |

10000L |

|

Pure water tank (added available) |

500L |

1000L |

2000L |

3000L |

5000L |

10000L |

|

Recycling water tank(added available) |

2000L |

2000L |

5000L |

10000L |

15000L |

20000L |

|

Heating method |

Plate change (tube change) + steam heating

|

Plate change (tube change) + steam heating

|

Plate change (tube change) + steam heating

|

Plate change (tube change) + steam heating

|

Plate change (tube change) + steam heating

|

Plate change (tube change) + steam heating

|

Performance parameter

Structural characteristics:

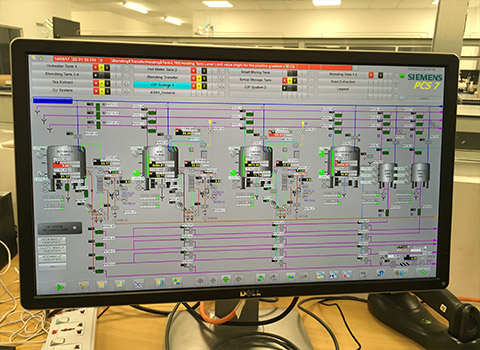

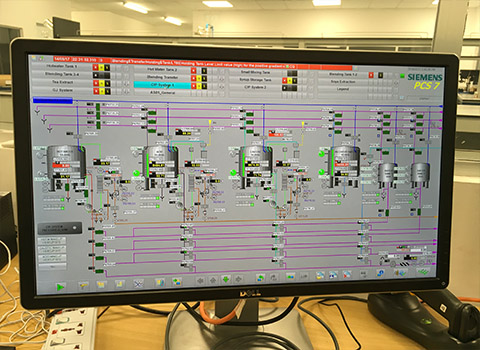

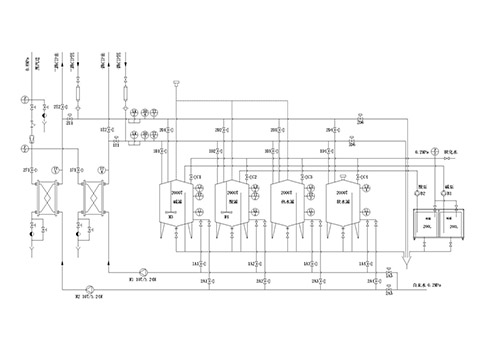

The system consists of 1 acid tank, 1 lye tank, 1 hot water tank, 1 pure water tank, plate (tube) heat exchanger, 1 original acid tank, 1 raw alkali tank, and cleaning. 1 pump (adjustable flow frequency conversion), 2 heating circulation pumps, return pipe, outlet pipe, water supply pipe and control system. According to the set control program, the cleaning liquid is automatically configured by the CIP cleaning system, and the cleaning process is carried out by the pneumatic control valve, the booster pump and the reflux pump to complete the cleaning and return circulation cleaning, discharge and recovery of the entire cleaning process. Automatic online cleaning is achieved through a control system consisting of a pH meter, a conductivity meter, temperature control, and a PLC touch screen. Each cleaning procedure, such as time, flow, acid-base concentration, can be inspected and recorded, printable and outputted, while ensuring that the cleaning temperature and concentration are automatically controlled during the corresponding cleaning process.

Performance characteristics:

(1) High degree of automation, automatic liquid feeding and automatic cleaning;

(2) Automatic dosing;

(3) Automatic temperature control;

(4) Automatic flow control;

(5) Automatic mixing of acid and alkali;

(6) Compact structure and elegant appearance;

(7) Strong independence, can be used alone, or can be docked with the automatic control system.

Related equipment: