- Tel: 0086-21-37901188

- E-mail: info@triowin.com

- whatsapp: +8613301885621

- wechat: 13301885621

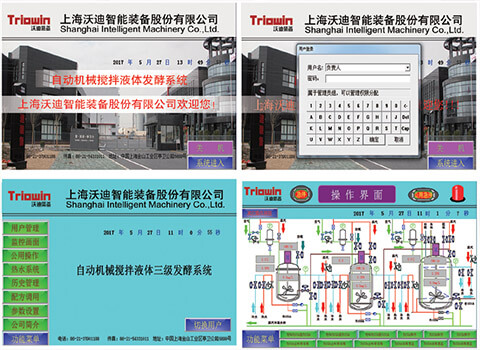

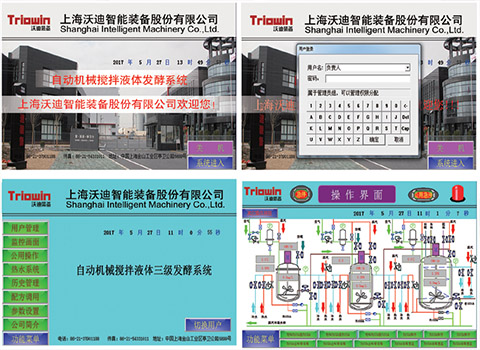

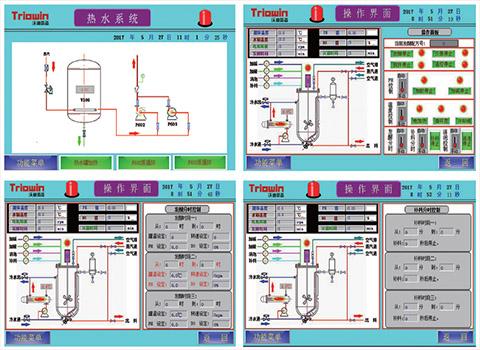

Control system

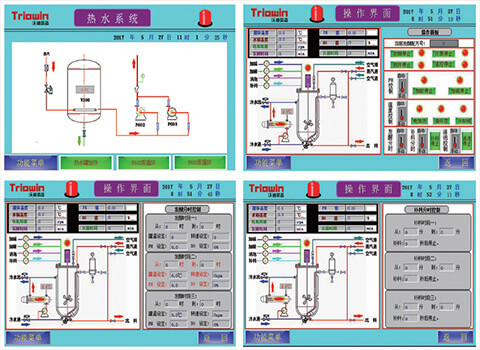

Triowin equipment has the ability to design professional fermentation control system software and custom software.The whole fermentation line control system has a high degree of automation. Signal linkage control is adopted among all the equipment to ensure the non-destructive operation of the equipment.Special fermentation process design ensures the amplification stability of fermentation process, reduces the investment risk of equipment, and meets the process requirements of anaerobic facultative anaerobic and aerobic bacteria products.The control components are all first-class international imported brands, such as ABB,SIEMENS,DANFOSS, SCHNEIDER,METTLER TOLEDO, etc.

Triowinintelligent equipment provides integrated upstream and downstream core process solutions,including bioreactor/fermentation tank system, medium preparation system, instantaneous continuous disinfection system, purification system, buffer solution preparation and sterilization system, and supporting CIP station system, clean utility distribution system.Our design ensures minimal product loss, optimized CIP and SIP functionality, and ease of operation and maintenance.Based on the whole process control, ensure that the final process risk is controllable and in line with expectations.As a complete solution provider including upstream and downstream and fermentation, we can help reduce cross construction interfaces, greatly improving project execution efficiency and overall project controllability.

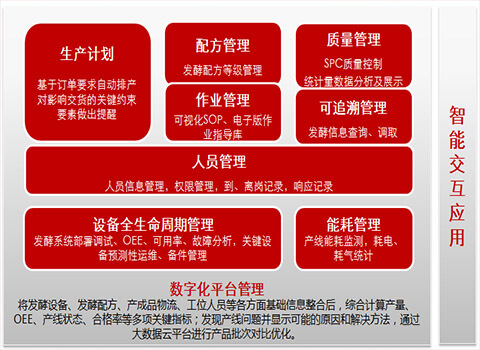

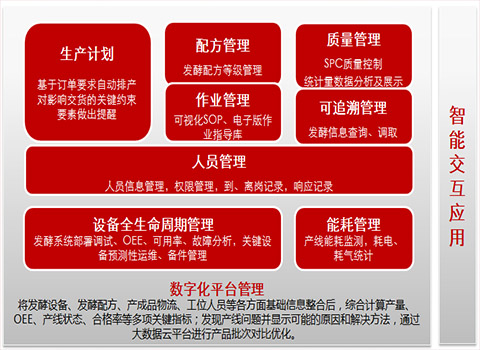

On the Siemens WinCC software platform, added the self-developed add-on production management module of SFAE, which can provide Automation MES for OEM large-scale equipment and production lines.Automation MES can be the connection between device layer and MES and ERP,as well as the basic Automation and SCADA system, which can be the basic conditions for the implementation of digital factory and can be operated independently.

MES scope of application:

1 .Information engineering for new equipment or production line;

2 .Upgrading and transformation of ex-factory equipment;

MES advantage:

1. Information management, improve the utilization rate of equipment;

2. After - sales quick diagnosis and maintenance;

3. Support end user lean production and reduce production management cost;

4. Realize data collection and management of production line;

5. Meet production traceability management

6. Flexible production can be realized;;

7. Quality control of production line;

8. Paperless electronic statements;