- Tel: 0086-21-37901188

- E-mail: info@triowin.com

- whatsapp: +8613301885621

- wechat: 13301885621

Overview:

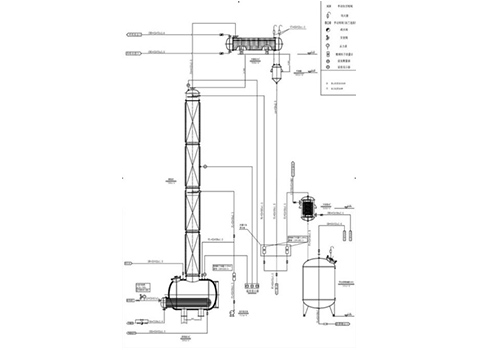

The alcohol recovery tower consists of six parts: tower kettle, tower body, condenser, cooler, buffer tank and high-level storage tank. It is suitable for the recovery of dilute alcohol in pharmaceutical, food, light industry, chemical and other industries. It is also suitable for methanol and other of coal-soluble products distillation. The equipment material filling adopt to high efficiency stainless steel packing. The parts in contact with the material are made of SUS304 or SUS316L. The outer surface of the equipment is matt treated, which has good corrosion resistance, and has the advantages of energy saving, environmental protection, lower production cost and improved efficiency. The device can distill the dilute alcohol of 12 ° ~ 50 ° to 93 ° ~ 95 °, the residual liquid discharge has low alcohol content, in line with GMP pharmaceutical standards.

Parameter

|

Parameter |

JH-200 |

JH-300 |

JH-400 |

JH-500 |

JH-600 |

JH-800 |

|

Tower diameter (㎜) |

200 |

300 |

400 |

500 |

600 |

800 |

|

Tower height( m) |

6 |

7 |

7 |

11 |

11 |

11 |

|

Kettle volume( L) |

600 |

1120 |

1450 |

2200 |

2200 |

2200 |

|

Recycle ability L/h |

60-80 |

100-120 |

120-150 |

350-400 |

350-400 |

350-400 |

|

Recovery concentration |

93%~95% |

|||||

|

steam pressure |

0.09Mpa |

|||||

|

System pressure |

Normal pressure |

|||||

|

Heating area (㎡) |

3.2 |

5.0 |

6.5 |

10 |

15 |

24 |

|

Condensation area (㎡) |

6.7 |

8.8 |

11 |

30 |

36 |

42 |

|

Cooling area (㎡) |

2 |

3 |

3.5 |

4 |

6 |

9 |

|

Length ( mm) |

2300 |

2600 |

2600 |

4000 |

4000 |

4000 |

|

Width ( mm) |

700 |

800 |

1000 |

1800 |

1800 |

1800 |

|

Height ( mm) |

≈8000 |

≈9000 |

≈10000 |

≈11000 |

≈12000 |

≈14000 |

Control options:

1. Drug / batch automatic control

2. Automatic control of material feeding/discharging flow

3. Automatic control of distillation tower temperature

4. Automatic control of liquid level at the bottom of distillation tower

5. Reflux ratio automatic control

6. Automatic control recovery of concentration

7. Cooling circulating water automatic control

8.CIP automatic cleaning

9. Production safety control

10. Control method (PLC/DCS system)

Structural characteristics:

1. High recovery capacity;

2. The concentration range is wide, the dilute alcohol of 12°~50° can be distilled to 93°~95°, and the residual liquid discharge has low alcohol content;

3. The equipment is highly integrated and the structure design is beautiful;

4. The whole machine can be designed to be fully automatic control, with high degree of automation and sensitive alcohol concentration monitoring;

5. Low energy consumption, high utilization rate of waste heat, energy saving and emission reduction;

Process flow: